In our last blog post, we talked about how maintaining small, positive changes over a period of time can bring about solid returns. The idea of achieving a goal doesn’t seem overwhelming when we look at it this way, and we are more likely to maintain our progress as we are not being asked for monumental, superhuman efforts every single day.

As we also pointed out, it helps to discontinue certain small, negative behaviours that, over the long run, add up to fairly substantial impediments or growth-negaters. For example, if you are chronically late to work everyday by ten minutes and don’t make up that time anywhere else, you will eventually lose a sizable chunk of time. Over the course of three months, you’re looking at 12.5 hours. That’s quite a bit. On top of that, you are probably not starting your day off with a clear mind because you are rushed, stressed, and the space in your brain is taken up with a whole range of negative feelings because you are late. There’s not much space left for healthy, productive, positive behaviours. If you turn this around, however, and start arriving 10 minutes early, then you will be giving yourself the gift of an easily-found extra 12.5 hours over three months PLUS a mind that is less-stressed and calmer, more able to start the day successfully.

With these ideas in mind, a challenge you can set yourself involves two things:

- Which behaviours, actions or improvements can you begin including in your day that might seem small but are actually important? For example, I really don’t like looking at my bank balance on a regular basis (even when I’m doing okay) just because I dread finding out that I am in worse shape than I thought. In the times that I have been able to get into the habit of checking my balance daily (ideally in the morning), I have been able to plan correctly and save myself from being overdrawn or slowly chewing away at my bank account through unnecessary transactions. At times, I have been able to hold onto cash for emergencies that have arisen, or even invested it somewhere. That is always a positive thing.

- The flip-side of this is what kinds of small, negative, perhaps lazy habits can you eliminate over a period of time in order to end up with a positive result? A classic example is take-away coffee. Going to your local coffee shop every morning on the way to work and getting a latte starts to add up. Take-out coffee on its own can easily reach an extra $100/month, and in order to eliminate this cost, you just need to set up the habit of making enough coffee for yourself at home before you leave the house. Setting up a new habit and breaking an old one can seem like a tall order at times, but if we actually give ourselves that time to get used to things, we will be successful (and, in this case, a little bit richer).

In both of these cases, finding different things to change involves seeing where you are already doing something well, and adding one more positive behaviour to it, or, seeing where you’re doing something that ends up being a negative and eliminating. In both cases, it’s just a matter of taking some time and analyzing basic behaviours.

With TPI, there are also ways that our system can help you, in small, incremental amounts to achieve greater profit and success. Once you are up and running with the system and have gotten used to the different basic functions, you can start branching out and taking a look at some different features. Here are a couple that are entirely beneficial when implemented as regular, rapid routines.

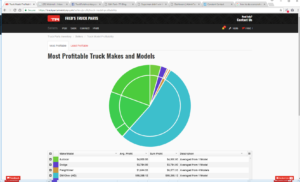

- Truck Model Profitability: in the Sellers’ Account Settings, go to Profit and then Reports. From there, you go to Inventory and then to Truck Model Profitability. This report quickly tells you which models are selling the best and it is a quick visual snapshot that, if you look at it regularly, will help you direct your future purchases on a consistent basis.

- Missed Sales: a technical explanation of how to use this feature is on our support site, but essentially it is a handy way to track what kind of items you might want to start including in your inventory if there seems to be a demand for them. Like the Truck Model Profitability feature, Missed Sales can be easily fit into a morning routine to help orient the days and your purchases.

- TPI is full of many different features, and most of them can be quick and easy to use. Take a look at this blog post and this one, and you will have a handy set of twenty new ideas that can help you get where you want to go, faster.

Overall, using TPI is quick and easy, and even it’s most basic features will help you save time simply by being more organized and systematic. Adding in any of the different features we have mentioned here will only increase your profitability as you maintain a closer relationship with what is actually happening and can make better decisions for the future. We encourage you to implement features one by one, and you’ll start to see a difference in a very short period of time.