By incorporating new, electric heavy trucks into their fleets, older diesel-powered trucks will be gradually phased out. Those that cannot be retrofitted or upgraded at a reasonable cost will be sold to smaller industries still reliant on traditional trucks or even recyclers if they’re attentive enough.

This surge in the supply of diesel-powered trucks will be a boon to the truck recycling industry, where otherwise common parts such as Freightliner CPCs (Common Powertrain Controllers) have been difficult to find. With a group like Freightliner producing their e-Cascadia electric trucks consistently, they will be moving away from having as many traditional trucks in their fleet, creating an opportunity for recyclers to get their hands on top-quality trucks and parts.

That’s not where it ends either. With OEMs (Original Equipment Manufacturers) moving to more electric and sustainable products, they’ll manufacture fewer parts for their previous diesel-powered counterparts. That means instead of people looking for parts going to the original manufacturer, they’ll go to the recyclers and aftermarket dealers to get their hands on the parts that Freightliner no longer makes.

Therein lies the opportunity for recyclers and salvage yards. If these parts and trucks are currently available from OEMs and dealerships, why not shell out a little extra cash to get a good-condition truck that you can then fix up, polish and sell? Or, as an alternative, take out all the key components like the engine and transmission, and replace them with recycled or remanufactured components.

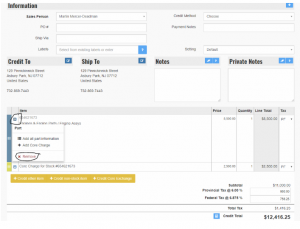

A function like TPI’s Gravy Parts will help yards maximize their profit off these newer items as well. The main components of a truck we mentioned earlier, like engines, transmissions and such, are usually the money makers for recyclers. But all the extra parts attached to that truck, like cross members, wheel hubs and wiring harnesses, still have value. That’s why we call them the “gravy” parts because they’re not the “beef and potatoes” of the truck.

Those gravy parts still have value that is attributed to the truck you got them from. By using TPI, you’ll have an excellent idea of how much money your trucks will get you, and by extension, a clearer idea of the value of each of your trucks. Of course, by having a list of the most profitable trucks, you also have a list of salvage to stay away from. Why spend money purchasing salvage that won’t make you money and just sits in your yard like an anchor?

Imagine you can’t find a part for your 2000 Freightliner Cascadia. Now imagine that you go to the first logical place to get a replacement – the manufacturer or dealer. Only, they tell you that they don’t have any of the parts in stock because they don’t make them anymore, or whatever excuse they peddle. Now imagine you find the part you need from a recycler who has an old Cascadia. The quality of the parts will be almost identical (save for some cosmetic work), cheaper and easier to find. Not to mention, you won’t be contributing to pollution because they won’t need to manufacture a new part for you – The benefit of recycling.

Regarding heavy EMVs, the void they create with their introduction will need to be filled by the recycling industry. More dependence on electric technologies in trucking will inevitably push the smaller carriers that can’t afford to go electric to the recyclers who still carry the parts they need for their vehicles. That’s not to mention the price-gouging that usually accompanies parts from the distributor or manufacturer.

Most of the larger groups are only concerned with making a profit, and they are usually large enough to do so at the expense of the consumer with minimal effects on the rest of the business. This is even more so now that many larger groups have invested so much money into electrification. The investment is and will continue to be costly, and they want to recoup their losses.

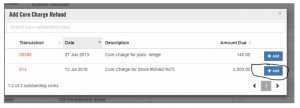

For instance, we had a customer who had ordered a 2012 ECM (Engine Control Module) for their Cummins engine. Usually, those sell for around $1000, give or take. However, the manufacturer wanted to charge upwards of $1400 for it simply because it was new. We directed this customer to one of our sellers who could offer the part in great condition for significantly less than the OEM wanted (about $600 less, to be specific).

Our seller was able to provide the customer with an ECM for less because recyclers work to help the industry, not just to make a profit. When the recyclers get their equipment for substantially less than what an OEM would ask for, they’re able to offer that equipment to customers in need, improve our industry, and do this all at an affordable rate.

This is the opportunity that recyclers and salvage yards have to start cutting down on these parts shortages. The heavy-duty recycling industry needs to jump at the chance to acquire these high-demand parts and use them to elevate our entire industry.

The more people rely on the OEMs for their parts, the more money they lose. And, the less people recycle.

Click here to learn more about Truck Parts Inventory (TPI).

This article was first shown in autorecyclingworld.com. To read the original magazine version click here.

Their insight? Over-prepare. You can never have too much inventory these days.

Their insight? Over-prepare. You can never have too much inventory these days.