The used semi truck parts market has been growing in recent years, despite OEM (Original Equipment Manufacturer) dominance, and there are several reasons as to why used parts are often a better choice than brand new parts. With everything from cost savings to reliability, there is little reason you should be paying full price for what the OEM’s offer, when you can get a better deal all around through the used heavy truck parts market.

The most obvious reason for choosing used semi truck parts is cost savings. Used parts can often be purchased for a fraction of the cost of brand new parts, making it a much more affordable option for both Owner Operators (O/O) and carrier companies looking to maintain their vehicles.

When it comes to availability, used semi truck parts are often readily available, even for older or less common vehicles. This is a major advantage for some companies, as it allows them to quickly source the parts they need to keep their vehicles on the road.

New parts often come with warranties or guarantees that can provide added protection against manufacturing defects or other issues that may arise. And the assumption is that used truck parts won’t come with a warranty. This assumption may be true for a lot of the industry, but certainly not for TPI sellers. The main difference being that TPI sellers aren’t just in it for the money or business growth, they’re in it to help the industry that keeps almost everything moving.

In fact, you’ll find that many TPI sellers offer warranties and guarantees on their inventory items as well. Because after all, if your truck breaks down due to a part issue, they genuinely want to help you and get your truck moving again. If your truck is out of operation, whatever it is that you’re hauling doesn’t move and you as the driver likely aren’t making any money. TPI sellers understand this and aim to fix it.

Despite the lower cost and the general assumption that used parts are worse, used semi truck parts are often of high quality and are rigorously tested before being sold, especially by TPI sellers. This means that used parts can be just as reliable as brand new parts, providing trucking companies and drivers with peace of mind while reducing the risk of unexpected repairs.

That being said, it’s important to note that not all new parts are created equal either. The reliability of a new part can vary depending on the quality of the manufacturing process, the materials used, and the reputation of the manufacturer. In some cases, a new part may be defective or may fail prematurely due to a flaw in the manufacturing process. This could cost you a lot more money than used parts would and you know that the used parts would work, because they’ve been used before.

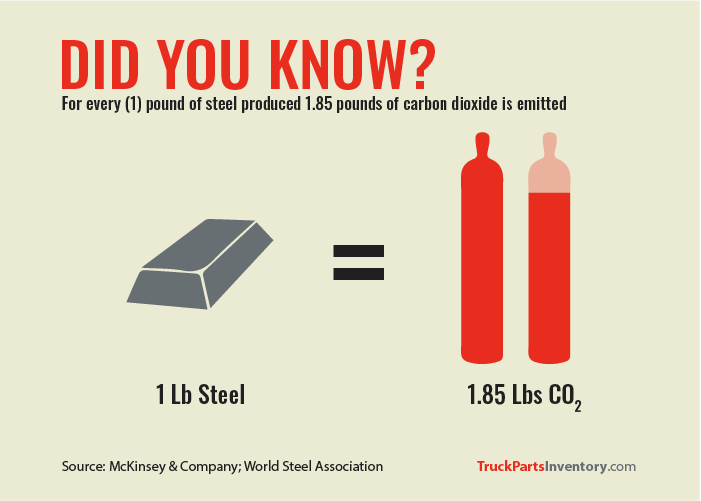

Another advantage of using used semi truck parts is that it reduces the environmental impact of manufacturing new parts. The production of new parts requires a significant amount of energy and resources, and by using used parts from TPI, trucking companies can help to reduce their carbon footprint. TPI is constantly tracking the amount of steel saved from landfills via our sustainability promise.

Again, there are several reasons why used semi truck parts are a better choice than brand new parts. From cost savings to environmental impact, used parts offer a range of benefits that make them an attractive option for trucking companies, salvage yards, remanufacturers and repair facilities. With the growing demand for used parts and your help meeting it, the used semi truck parts market is poised for continued growth in the years to come.